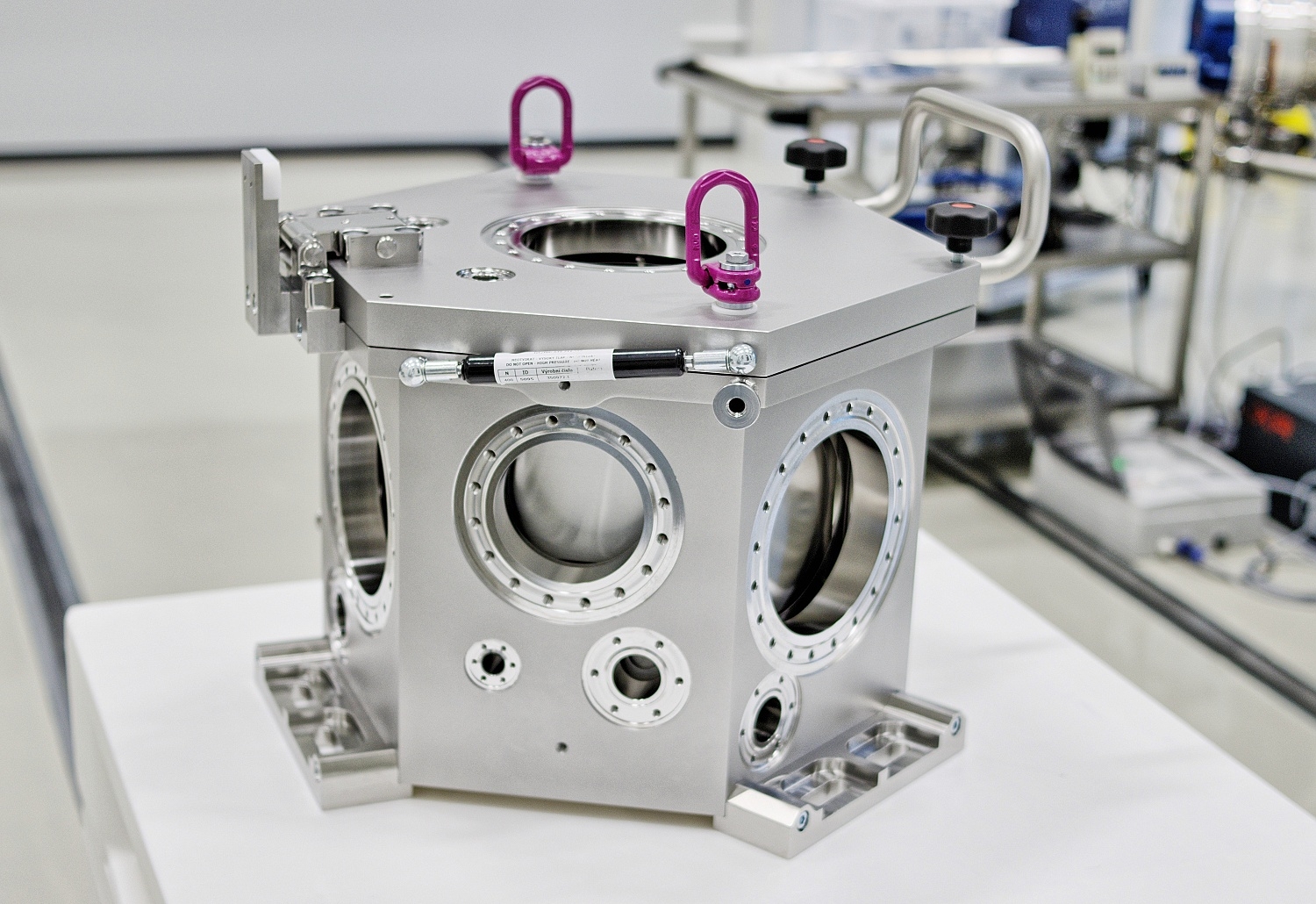

The hexagonal chamber, measuring 45 × 35 cm, was manufactured from a single piece of stainless steel, ensuring exceptional tightness and structural stability even under extreme conditions. Using liquid nitrogen, it is capable of reaching temperatures as low as –180 °C, while electric heating allows it to be heated up to +200 °C. This wide temperature variability simulates the conditions that prevail in space – from freezing shade to direct sunlight. The chamber has undergone mechanical and electrolytic polishing and was assembled in clean rooms of ISO 6 to ISO 8 class, which corresponds to the strict ESA standards for working with space hardware.

STREICHER Plzeň has long specialized in the manufacture of precision technological equipment for the energy industry, vacuum and cryogenic systems, and scientific research. In recent years, it has also expanded its activities into the field of space technology, where it applies its experience in the design of pressure and vacuum systems, high-precision metal machining, and quality assurance in accordance with ECSS (European Cooperation for Space Standardization) standards.

Its cooperation with ESA confirms the technical sophistication and qualification readiness of the company, which has become a supplier of equipment for testing space hardware. The thermal vacuum chamber from Plzeň is now expanding the facilities of the ESTEC laboratories, where it will be used to test electronics, sensors, and materials exposed to space environment conditions.